What Is a Motor Controller? A Practical Buying Guide for Selecting the Right Type

Motor controllers are at the heart of countless modern machines, from electric cars and drones to factory automation and household appliances. Whether you realize it or not, almost every device that uses an electric motor relies on a controller to function safely, efficiently, and precisely. But what exactly is a motor controller, how does it work, and why is it so important?

This article explores the role of motor controllers, their different types, applications, and the key considerations when choosing one.

What is a motor controller?

At its simplest, a motor controller is an electronic device that regulates the operation of an electric motor. It acts as the interface between the power source and the motor, controlling factors such as speed, torque, and direction.

Without a controller, an electric motor would simply run uncontrolled at full power whenever connected to electricity—something that is rarely useful in practice and often unsafe. By controlling the flow of electrical energy, the controller ensures the motor delivers exactly the performance required for the task at hand.

Why Motor Controllers Matter

Electric motors are highly versatile, but they are not inherently intelligent. A bare motor has no ability to regulate itself. The motor controller provides:

- Precision: Fine control over speed and position, essential for robotics, CNC machines, and medical devices.

- Efficiency: Optimized power delivery to minimize energy loss, critical for battery-powered systems like electric vehicles.

- Protection: Safeguards against overcurrent, overheating, and short circuits to extend the motor’s life.

- Flexibility: Ability to reverse direction, ramp speeds smoothly, and adapt to different load conditions.

Put simply, the controller unlocks the full potential of the motor.

Types of Motor Controllers

There is no single “best” motor controller. Different motor technologies — such as brushed DC, stepper, brushless DC (BLDC), sensorless BLDC, and asynchronous (induction) motors — each have distinct electrical and mechanical characteristics. As a result, their controllers vary significantly in terms of topology, control algorithms, complexity, and cost.

For example, some applications prioritise precise position control, while others require high efficiency at variable speeds or robust operation in harsh environments. In some cases, simplicity and low cost are key; in others, advanced control techniques such as field-oriented control (FOC) are essential to meet performance targets.

This guide provides a clear overview of the main types of motor controllers in common use today. Each section explains how the controller works, which motor types it supports, its advantages and limitations, and the kinds of applications it is best suited to. Whether you are specifying a system for the first time or refining an existing design, understanding these differences is an important step toward selecting the right motor control solution.

Read on below to learn more about the specific types of motor controller available...

| Motor Controller Type | Typical Control Method | Position Feedback Required | Key Advantages | Key Limitations | Typical Applications |

|---|---|---|---|---|---|

| Brushed DC | PWM voltage & current control, H-bridge | Optional (open or closed loop) | Simple, low cost, easy to implement | Brush wear, lower efficiency, electrical noise | Actuators, small pumps, conveyors, automotive subsystems |

| Stepper | Step sequencing, microstepping, current control | No (optional in closed-loop systems) | Accurate positioning, simple control, good low-speed torque | Torque drops at speed, resonance, possible lost steps | CNC, 3D printers, medical devices, lab automation |

| BLDC (Sensored) | Six-step, sinusoidal, or FOC | Yes (Hall sensors or encoder) | High efficiency, smooth control, long service life | Higher cost and complexity, sensor dependency | Pumps, robotics, EVs, industrial automation |

| BLDC (Sensorless) | Back-EMF or observer-based control, sensorless FOC | No | Reduced cost, fewer components, high reliability | Limited low-speed control, complex startup | Fans, compressors, appliances, cost-sensitive industrial systems |

| Asynchronous (Induction) | V/f control, vector control, FOC | No (optional encoder) | Rugged, widely available motors, scalable to high power | Lower efficiency at light load, complex control | HVAC, pumps, conveyors, heavy machinery |

Brushed DC Motor Controllers

Brushed DC motor controllers are among the simplest and most widely used forms of motor control. They are designed to drive brushed direct current (DC) motors, which use mechanical brushes and a commutator to switch current through the motor windings. Because commutation occurs mechanically within the motor, the controller itself can be relatively straightforward.

At a basic level, a brushed DC motor controller regulates the voltage applied to the motor to control speed, and the current supplied to control torque. This is most commonly achieved using pulse-width modulation (PWM), where the controller rapidly switches the supply voltage on and off to achieve an effective average voltage at the motor terminals. Direction control is typically implemented using an H-bridge circuit, allowing the polarity of the motor voltage to be reversed electronically.

One of the main advantages of brushed DC motor controllers is their simplicity. They require minimal configuration, no knowledge of rotor position, and little computational overhead. This makes them cost-effective and easy to integrate, particularly in low- to medium-power applications. As a result, they are often used in systems where speed control is required but high precision or efficiency is not critical.

Brushed DC controllers can operate in either open-loop or closed-loop configurations. In open-loop systems, the controller simply applies a commanded voltage or duty cycle, with no feedback on actual speed or torque. Closed-loop systems incorporate feedback from sensors such as encoders, tachometers, or current sensors, allowing the controller to regulate speed or torque more accurately and compensate for load changes.

Despite their advantages, brushed DC motor controllers also have limitations. The brushes and commutator within the motor are subject to mechanical wear, which reduces reliability and requires maintenance over time. Electrical noise generated by brush switching can also be an issue in sensitive environments. In addition, brushed motors are generally less efficient than brushless alternatives, particularly at higher speeds or power levels.

For these reasons, brushed DC motor controllers are most commonly found in applications such as small pumps, actuators, conveyors, automotive subsystems, and cost-sensitive industrial or consumer products. While they are increasingly being replaced by brushless technologies in high-performance systems, brushed DC controllers remain a practical and effective solution where simplicity, robustness, and low upfront cost are the primary drivers.

Stepper Motor Controllers

Stepper motor controllers are designed to drive stepper motors, which move in discrete angular increments, or “steps,” rather than rotating continuously. This characteristic allows stepper motors to achieve precise position control without the need for external position feedback in many applications, making them popular in systems where simplicity and repeatability are important.

A stepper motor controller works by energising the motor’s windings in a carefully timed sequence, causing the rotor to advance by a fixed step angle. The most common stepper motors are bipolar and unipolar, with bipolar motors requiring more complex drive electronics but offering higher torque for a given motor size. Modern stepper controllers almost exclusively support bipolar motors, using full H-bridge drive stages for each phase.

Early stepper motor controllers operated in full-step or half-step modes, where the motor moved in relatively coarse increments. Most modern controllers now use microstepping, in which the current in each winding is modulated to create intermediate magnetic field positions. Microstepping significantly improves motion smoothness, reduces vibration and audible noise, and increases usable resolution, often to hundreds or thousands of microsteps per revolution.

Current regulation is a key function of a stepper motor controller. Because stepper motors are typically driven from a fixed supply voltage, the controller actively limits and shapes the phase current using techniques such as chopper current control. This allows the motor to develop high torque at low speeds while protecting both the motor and controller from overcurrent conditions.

Stepper motor controllers are usually operated in an open-loop configuration, where the controller assumes that each commanded step has been executed correctly. This works well when the motor is correctly sized and operated within its torque limits. However, if the load exceeds the available torque, the motor may lose steps without any direct indication to the controller. For more demanding applications, closed-loop stepper systems are available, combining a stepper motor with an encoder and feedback control.

Stepper motor controllers excel in applications requiring accurate positioning at low to moderate speeds, such as 3D printers, CNC machines, pick-and-place equipment, medical devices, and laboratory automation. Their main limitations include reduced efficiency, significant torque drop-off at higher speeds, and the risk of resonance or vibration if not properly configured.

Despite these constraints, stepper motor controllers remain a highly effective solution where predictable positioning, straightforward control, and cost-effective implementation are more important than maximum efficiency or dynamic performance.

Brushless DC Motor Controllers

Brushless DC (BLDC) motor controllers are used to drive brushless permanent magnet motors, which eliminate mechanical brushes and commutators in favour of electronic commutation. In these motors, the rotor contains permanent magnets and the stator contains the windings. The controller’s role is to energise the stator phases in the correct sequence to produce continuous rotation and controlled torque.

Unlike brushed DC motors, BLDC motors require the controller to know the rotor position in order to commutate the motor correctly. This information is typically provided by Hall effect sensors embedded in the motor, or by high-resolution encoders in more demanding applications. Using this feedback, the controller switches the power devices driving each motor phase at the appropriate time.

Most BLDC motor controllers use a three-phase inverter consisting of six power switches arranged in a bridge configuration. The simplest control method is six-step (trapezoidal) commutation, where two phases are energised at a time, producing a trapezoidal back-EMF waveform. This approach is relatively easy to implement and is well suited to applications where cost and simplicity are important.

More advanced BLDC controllers use sinusoidal commutation or field-oriented control (FOC). These techniques shape the phase currents to produce a smooth rotating magnetic field that is aligned with the rotor magnets. The result is significantly reduced torque ripple, lower acoustic noise, improved efficiency, and better dynamic performance, particularly at low speeds.

BLDC motor controllers offer several key advantages over brushed alternatives. The absence of brushes eliminates mechanical wear, greatly improving reliability and service life. Higher efficiency reduces power consumption and heat generation, making BLDC systems well suited to battery-powered and energy-sensitive applications. In addition, BLDC controllers can support advanced features such as regenerative braking, torque control, and detailed fault monitoring.

However, these benefits come at the cost of increased complexity. BLDC controllers require more sophisticated electronics, higher processing capability, and careful tuning of control parameters. They are also more sensitive to electrical noise and require good system-level design to achieve optimal performance.

BLDC motor controllers are widely used in applications such as pumps, fans, compressors, robotics, electric vehicles, and industrial automation. They are particularly attractive where long lifetime, high efficiency, and precise control are essential. As control algorithms and processing power continue to improve, BLDC controllers have become the preferred solution for many modern motor-driven systems.

Sensorless Brushless DC Motor Controllers

Sensorless brushless DC (BLDC) motor controllers are a variant of BLDC control systems that eliminate the need for physical rotor position sensors such as Hall effect devices or encoders. Instead, the controller estimates the rotor position using electrical measurements taken from the motor itself. This approach reduces component count, wiring complexity, and cost, while also improving reliability in harsh environments.

The most common sensorless technique relies on measuring the motor’s back electromotive force (back-EMF). As a BLDC motor rotates, the permanent magnets on the rotor induce a voltage in the stator windings. By monitoring the back-EMF of the unpowered phase, the controller can infer the rotor position and determine the correct timing for commutation. This method works well once the motor is spinning at sufficient speed for the back-EMF signal to be clearly detectable.

Because back-EMF is proportional to speed, sensorless BLDC controllers face challenges at low speed or standstill, where the signal is very small or nonexistent. To overcome this, the controller typically uses a predefined start-up sequence, applying a controlled open-loop commutation pattern to accelerate the motor until reliable position estimation becomes possible. More advanced systems use model-based observers or high-frequency signal injection to extend sensorless operation into lower speed ranges.

Sensorless BLDC controllers can be implemented using simple six-step commutation or more advanced techniques such as sensorless field-oriented control (FOC). Sensorless FOC offers many of the same benefits as sensored FOC — smooth torque production, high efficiency, and precise control — but requires significantly more processing power and careful tuning of motor parameters.

The main advantages of sensorless BLDC motor controllers are reduced cost, improved robustness, and simplified motor construction. Removing position sensors eliminates a common failure point and allows motors to operate in environments with high temperature, vibration, moisture, or contamination. It also simplifies cabling, which can be a major advantage in compact or high-volume products.

However, sensorless control also introduces trade-offs. Start-up behaviour can be less predictable, especially under high load, and very low-speed or zero-speed torque control is more difficult than with sensored systems. Performance is also more dependent on accurate motor models and clean electrical signals.

Sensorless BLDC motor controllers are widely used in pumps, fans, compressors, household appliances, and cost-sensitive industrial products. They are particularly well suited to applications that operate predominantly at medium to high speeds and where long-term reliability and reduced system complexity are key priorities.

Asynchronous (Induction) Motor Controllers

Asynchronous motors, more commonly known as induction motors, are one of the most widely used motor types in industrial applications. Unlike DC or brushless permanent magnet motors, induction motors do not rely on magnets or brushes. Instead, torque is produced by electromagnetic induction between the stator’s rotating magnetic field and currents induced in the rotor. An asynchronous motor controller is responsible for generating and regulating this rotating magnetic field.

Induction motor controllers are typically implemented as variable frequency drives (VFDs) or inverters. These systems convert a fixed-frequency AC supply into a variable-frequency, variable-voltage output that allows precise control of motor speed and torque. By adjusting the frequency of the applied voltage, the controller directly controls the speed of the rotating magnetic field, and therefore the motor’s operating speed.

The simplest induction motor controllers use volts-per-hertz (V/f) control, maintaining a constant ratio between voltage and frequency to keep the motor’s magnetic flux within an optimal range. This approach is robust, cost-effective, and suitable for applications such as pumps, fans, and conveyors where dynamic performance requirements are modest.

More advanced induction motor controllers use vector control or field-oriented control (FOC) techniques. These methods decouple torque and flux control by mathematically transforming motor currents into a rotating reference frame aligned with the motor’s magnetic field. Vector-controlled drives provide significantly improved torque response, efficiency, and low-speed performance, often approaching that of permanent magnet motors.

Induction motor controllers are usually sensorless, estimating rotor speed and position based on measured currents and voltages. While encoders can be added for high-performance applications, many modern drives achieve excellent performance without them, reducing system cost and complexity.

One of the key advantages of induction motor controllers is their compatibility with motors that are rugged, inexpensive, and widely available. Induction motors are tolerant of high temperatures, electrical noise, and harsh environments, and they require very little maintenance. They are also well suited to high-power applications, from a few hundred watts to several megawatts.

However, induction motor control is computationally demanding, particularly for vector-controlled systems. Efficiency is generally lower than that of permanent magnet motors, especially at light loads, and achieving precise low-speed or zero-speed torque control can be challenging without feedback sensors.

Induction motor controllers are commonly used in industrial automation, HVAC systems, compressors, pumps, elevators, and heavy machinery. Their proven reliability, scalability, and compatibility with standard AC power infrastructure make them a cornerstone of modern motor-driven systems.

Motor Controller: Key Features to Look For

Selecting the right motor controller is about more than simply matching voltage and current ratings. A well-chosen controller can improve system performance, efficiency, reliability, and ease of integration, while the wrong choice can introduce unnecessary cost, complexity, or risk. Understanding the key features to look for helps ensure the controller is well matched to both the motor and the application.

One of the first considerations is motor compatibility. The controller must support the motor type being used, such as brushed DC, stepper, brushless DC (BLDC), permanent magnet synchronous motor (PMSM), or induction motor. It should also support the required control method, whether simple open-loop control or more advanced techniques such as closed-loop speed, torque, or field-oriented control (FOC).

Electrical ratings are equally important. The controller must be capable of handling the motor’s operating voltage and continuous and peak current requirements, with sufficient margin for transient loads and startup conditions. Thermal management and derating behaviour should be clearly understood, particularly in compact or high-duty-cycle systems.

Control performance is another key factor. This includes speed and torque accuracy, dynamic response, and smoothness of operation, especially at low speeds. Features such as current regulation, ramping profiles, and configurable control loops can significantly affect how the system behaves in real-world conditions.

From a system integration perspective, interfaces and communications are critical. Support for standard control signals, industrial fieldbuses, or digital interfaces can simplify integration and future-proof the design. Diagnostic feedback, fault reporting, and parameter access are also valuable for commissioning and long-term maintenance.

Finally, consider robustness and lifecycle factors. Protection features such as overcurrent, overvoltage, thermal shutdown, and fault detection help safeguard both the motor and controller. Software configurability, documentation quality, and long-term availability can be just as important as headline performance, particularly in industrial or safety-critical applications.

By evaluating these features early in the specification process, it becomes much easier to select a motor controller that delivers reliable, optimised performance throughout the life of the product.

How Motor Controllers Work

The specific operation of a motor controller depends on the motor type it is driving. However, most controllers share a few common building blocks:

-

Power Electronics

- Transistors (such as MOSFETs or IGBTs) act as electronic switches to regulate current to the motor.

- Pulse Width Modulation (PWM) techniques chop up the voltage into high-frequency pulses, allowing precise speed control.

-

Control Logic

- A microcontroller, DSP, or dedicated control IC interprets user commands or sensor feedback and decides how the motor should respond.

- Algorithms such as Field-Oriented Control (FOC) or trapezoidal control determine how power is applied.

-

Feedback and Sensors

- Encoders, Hall-effect sensors, or back-EMF measurement provide information on position, speed, and load.

- Closed-loop control uses this feedback to correct errors and improve accuracy.

-

Protection Circuits

- Overcurrent detection, thermal shutdown, and soft-start functions help protect both the motor and the controller itself.

Applications of Motor Controllers

Motor controllers are everywhere, often hidden behind the scenes:

- Transportation: Electric cars, trains, and e-bikes all rely on sophisticated motor controllers for acceleration, regenerative braking, and efficiency.

- Industrial Automation: Robotics, conveyor belts, pumps, and machine tools all require precise motor control.

- Consumer Electronics: Fans, washing machines, and hard drives use small-scale controllers to regulate operation.

- Aerospace and Drones: Lightweight, high-performance controllers are critical for flight stability and battery life.

- Medical Equipment: Devices like infusion pumps and surgical robots demand high precision and reliability.

In each case, the controller transforms raw electrical energy into controlled, useful mechanical motion.

To find out more about the applications our motor controllers are used in please click here.

Challenges in Motor Control

Motor control systems are often expected to perform reliably for years in demanding environments, yet many of the challenges involved are not related to cutting-edge research or advanced algorithms. Instead, they arise from the practical realities of specifying, integrating, and operating motor controllers in everyday applications.

One of the most common challenges is matching the controller to the motor and load. Motors rarely operate under ideal or constant conditions, and real-world loads can vary significantly over time. Undersized controllers may struggle during startup or transient events, while oversized systems can introduce unnecessary cost and inefficiency. Accurately accounting for torque requirements, inertia, duty cycle, and operating margins is essential but often overlooked.

Startup and low-speed behaviour is another frequent source of issues. Applications that require smooth acceleration, controlled starting under load, or stable low-speed operation can expose weaknesses in both the motor and controller selection. This is particularly relevant for sensorless systems, where performance near standstill can be more difficult to achieve consistently.

Electrical noise and electromagnetic interference (EMI) present ongoing challenges, especially in systems combining power electronics, sensors, and communications. Poor grounding, cable routing, or filtering can lead to erratic behaviour, measurement errors, or intermittent faults that are difficult to diagnose and reproduce.

Thermal management is also a key concern in day-to-day operation. Motors and controllers generate heat, and inadequate cooling or incorrect assumptions about ambient conditions can lead to derating, reduced lifetime, or unexpected shutdowns. These issues often only emerge after extended operation or deployment in the field.

Finally, commissioning, tuning, and diagnostics can significantly affect system success. Controllers that are difficult to configure, lack clear feedback, or provide limited fault information increase setup time and make troubleshooting more complex. Over the life of a product, these factors can have a greater impact on cost and reliability than the core control algorithm itself.

Addressing these practical challenges early in the design process is key to achieving reliable, efficient, and predictable motor control in real-world applications.

The Future of Motor Controllers

Motor controllers are evolving rapidly, driven by increasing demands for efficiency, flexibility, and intelligence across industrial, commercial, and consumer applications. While the fundamental principles of motor control remain well established, the way controllers are designed, deployed, and used is changing in response to broader system-level trends.

One of the most significant drivers is the continued push for higher energy efficiency. Regulatory pressure and rising energy costs are accelerating the adoption of advanced control techniques such as field-oriented control (FOC), even in traditionally cost-sensitive applications. Improvements in processing power and power electronics are making high-performance control more accessible across a wider range of motor types and power levels.

Another key trend is the move toward greater integration. Modern motor controllers increasingly combine power electronics, control processing, sensing, and protection into compact, highly integrated modules. This reduces system size and complexity while improving reliability and manufacturability. Integrated motor-controller solutions are particularly attractive in applications where space, weight, and assembly time are critical.

Software and connectivity are also becoming central to motor control systems. Controllers are expected to support digital commissioning, parameter management, and communication with higher-level systems for monitoring and optimisation. This enables features such as condition monitoring, predictive maintenance, and remote diagnostics, helping users reduce downtime and improve overall system performance.

Sensorless control techniques continue to improve, extending reliable operation into lower speed ranges and more demanding load conditions. This reduces dependence on physical sensors and simplifies system design, especially in harsh or high-volume environments.

Looking ahead, the future of motor controllers will be shaped less by radical new motor types and more by smarter, more adaptable control platforms. Systems that are easier to integrate, configure, and optimise over their lifetime will increasingly be favoured, particularly as applications demand both higher performance and lower total cost of ownership.

Our Products and Services: Making Motor Control Decisions Simple

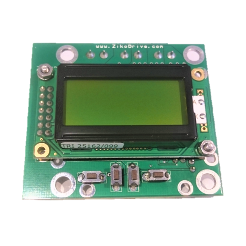

Specifying and deploying a motor controller can be complex, particularly when performance, efficiency, reliability, and cost all need to be balanced. At Zikodrive, our products and services are designed to remove that complexity and help customers achieve optimised motor control with confidence.

Our range of motor control solutions covers a wide variety of motor types and applications, including brushed DC, stepper, brushless DC (BLDC), permanent magnet synchronous motors (PMSMs), and sensorless systems. Rather than offering one-size-fits-all products, we focus on providing controllers that are carefully matched to real-world operating conditions, ensuring predictable performance and long-term reliability.

Beyond hardware, we place strong emphasis on software, configuration, and system-level support. Our controllers are designed to be straightforward to integrate and commission, with clear interfaces, robust protection features, and meaningful diagnostic feedback. This reduces setup time, simplifies troubleshooting, and helps systems perform as intended from day one.

We also support customers throughout the full lifecycle of their project. From early-stage specification and feasibility assessment through to optimisation, validation, and production support, our engineering-led approach helps identify potential issues early and avoid costly redesigns later. Where required, we can assist with control strategy selection, sensorless operation, tuning, and application-specific optimisation.

At the heart of our approach is a focus on making motor control decisions easier. By combining deep technical expertise with practical, application-driven design, we help customers select the right motor control solution without unnecessary complexity or risk.

Whether you are developing a new product or refining an existing system, Zikodrive provides the tools, knowledge, and support needed to deliver efficient, reliable, and optimised motor control.