Optimised Motor Controllers for Low Inductance and High-Speed Motors

Low-inductance motors offer performance advantages in high-speed and precision applications, but they require carefully designed controllers to operate reliably. Zikodrive specialises in motor controllers engineered specifically for low inductance motors, delivering efficiency and control where it matters most.

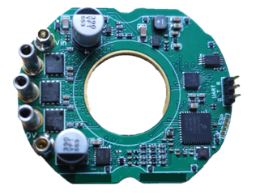

Our custom BLDC low-inductance motor controllers are designed for high-speed applications where precision and rapid switching are critical.

Why Low Inductance Motors Require Specialised Controllers

Low-inductance motors present unique challenges. Because of their low inductance, these motors can experience very rapid current changes, which can lead to inefficient operation and even damage if not managed correctly.

Standard motor controllers often can't handle the high switching frequencies required, leading to reduced performance and reliability issues.

Zikodrive solutions are designed to overcome these challenges. We use advanced control algorithms and specialised hardware to ensure stable, efficient, and precise operation, even under high-speed, dynamic conditions.

Features of Zikodrive Low-Inductance Motor Controllers

Optimised for high-speed and precision control.

Reliable operation with low inductance and BLDC motors.

Customisable firmware for specialist applications.

Reduced switching losses for greater efficiency.

UK engineering, design, and manufacturing support.

Applications in High-Speed and Specialist Environments

Our controllers are ideal for various applications, including robotics, automation, and industrial machinery, where high-speed and precision are essential. For example, a robotic arm requires a

high-performance motor controller that can handle rapid movements with extreme accuracy. A dedicated

low-inductance motor driver ensures the system operates smoothly and efficiently, even during complex, high-speed tasks.

We also offer bespoke motor control design services for unique project requirements, such as custom pump applications. Leveraging our expertise, we can create an integrated solution that is perfectly tailored to your needs.

Custom BLDC and Low Inductance Controller Solutions

We specialise in designing and manufacturing custom motor controllers for low inductance and brushless DC motors. Our solutions can be tailored to meet your exact specifications, ensuring perfect integration and maximum performance.

We provide comprehensive custom solutions, from design and prototyping to full-scale manufacturing, all with the support of our UK-based engineering team.

Low Inductance Motor Control FAQs

Low-inductance motors require carefully designed controllers to handle rapid current changes and high switching frequencies, which standard controllers often cannot manage. Controllers such as FOC or trapezoidal can struggle to pick up back-EMF signals accurately, meaning that accurate speed control is not possible. One response to this within controller design has been to increase the frequency of FOC, however this can rapidly reduce motor control efficiency.

In addition to this, low inductance can mean high current ripple placing controllers and motors under significant strain if not managed correctly.

That said, all of these problems are resolvable and manageable. In many cases the best solution to the issue relies on application specific information being used to inform the decision. If you have any questions on any of these issues please do contact our team to discuss your project.

Our controllers use advanced control algorithms and specialised hardware to ensure stable, efficient, and precise operation, delivering high-speed performance and reliability. Where high frequency FOC does not work well, there are a number of other options that can be used to ensure successful operation of your motor.

Perhaps the two most notable applications for low inductance motor control are applications where speed requirements are increasing significantly and those where power density requirements are essential for reliable operation. In such cases, typical examples would include drone motors, industrial CNC type spindles and a wide range of related applications. In drone motors, efficiency and power density (the amount of usable power for a given mass) are hugely important factors in improving overall product performance and effectiveness. A small increase in efficiency adds to useful performance in use (increased range of increased payload for example).

Equally, where high speed is required, lower inductance motor design can help improve performance.

Absolutely, yes. As with all projects, custom motor control solutions may well be the best option for your project or application.

The same process will apply as with all custom motor control projects. Find out more about custom design motor control here.