Integrated Motor Controllers, Custom Solutions for Pumps & PCB Mounting

Custom designed motor controllers, integrated into your product, to your specification

We understand that integrated motor controllers can significantly enhance your product design, improving both appearance and functionality.

Our small integrated motor controllers for pumps and motors are engineered for optimal thermal management, reducing wiring complexity.

You can choose from PCB-mounted, product-mounted or DIN-rail capable designs to dramatically cut assembly time. Controllers can be designed to integrate directly into your product or we can develop PCB's that integrate other aspects of your product into the design, reducing assembly time and risk.

We are based in West Yorkshire, and our design and manufacturing processes are certified to ISO-9001 standard.

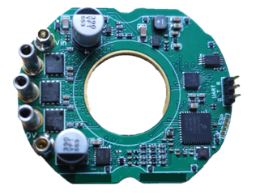

Small, integrated motor controllers for pumps

Our small integrated motor controllers for pumps are designed to be compact, improving aesthetics and functionality by making the final product smaller and more efficient. By integrating the controller directly into the pump casing, we provide solutions that are optimised for thermal management and performance.

Optimised for Thermal Management & Performance

Zikodrive's integrated motor controllers offer a thermal-management-optimised design. This improves thermal performance via an integrated casing design. We also offer optional connectors for flexible integration and overall performance improvements.

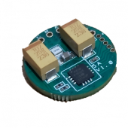

Reduce Assembly Time with PCB or DIN-Rail Integration

Our PCB-mounted motor controllers for reduced assembly time are designed to simplify the overall assembly process by incorporating many parts directly onto the PCB. We also offer DIN-rail motor controller integration solutions to simplify assembly and reduce the risk of wiring errors.

If you need a "shield" type motor controller custom designed to piggy-back onto an existing PCB we can work with you to deliver this. Talk to our team today to understand what the options are.

Key Features and Benefits

- Improved aesthetics and functionality.

- Improved thermal performance via an integrated casing design.

- Optional connectors for flexible integration.

- PCB-mounted or DIN-rail options to simplify assembly.

- Reduced assembly time.

- We can manufacture Custom Motor Controllers

- Manufactured in West Yorkshire under ISO-9001 standards.

FAQs

The specific thermal management benefits depend significantly on the design of the wider product. However, it is possible to achieve significant thermal management improvements in a number of ways. For example, controllers for pumps can be designed in such a way that fluid can flow close to the controller in normal use, enabling the fluid to act as a thermal transfer medium for the pump. In other cases, for example with motor casing integration, the motor controller can be designed to be mounted to the motor casing in a way that acts as a heatsink for the electronics. If used with potting compounds and/or other fixing methods, this can improve performance still further. Finally, where larger products are being manufactured we can develop controllers that can be directly integrated into existing thermal management systems (for example air or liquid based cooling). By working with you to understand your requirements, we can design the electronics in a way that enables the higher temperature parts of the controller to be positioned appropriately for your product.

Absolutely, yes! All Zikodrive Motor Controllers are designed and manufactured in the UK under our ISO-9001 accredited quality management system.

An integrated motor controller is a motor controller that has been specifically designed to be integrated into an existing product. For example a motor controller PCB that has been integrated into the casing design of a motor, pump or other device. There are a number of key advantages to using integrated motor control electronics in these situations, some of which are obvious, some of which are a little more nuanced. These are;

- Product design can look cleaner and tidier.

- The overall product is typically easier to setup and operate for the end user as much of the pre-assembly wiring has been done.

- Compliance with EMC standards can be easier to achieve as motor or pump casings can improve EMC performance.

If controllers are designed to be integrated into existing PCBs or DIN-rail systems then this can significantly reduce assembly time as connector choices can be made that enable quick integration. Equally, opportunities for error can be reduced by implementing polarity specific designs or connector choices so assembly staff can only assemble the controller in one way. Connectors can be designed to be mounted on the top or bottom side of the motor controller depending on your requirements to enable easy integration with other PCB designs.

As manufacturers ourselves, we fully understand the importance of reducing risk and defects through lean processes in manufacturing and we're happy to work with you to deliver a product which meets your requirements.

Contact us today for a free, no-obligation consultation on integrating motor controllers into your product design.