Brushless DC (BLDC) motors are at the forefront of modern motion control systems, offering advantages such as high efficiency, reliability, and compact design. While BLDC motors are inherently versatile, their full potential is unlocked through advanced control techniques like four-quadrant sensorless control. This article delves into the benefits of this sophisticated approach, particularly in demanding applications where efficiency, reliability, and flexibility are paramount.

What is 4-Quadrant Motor Control?

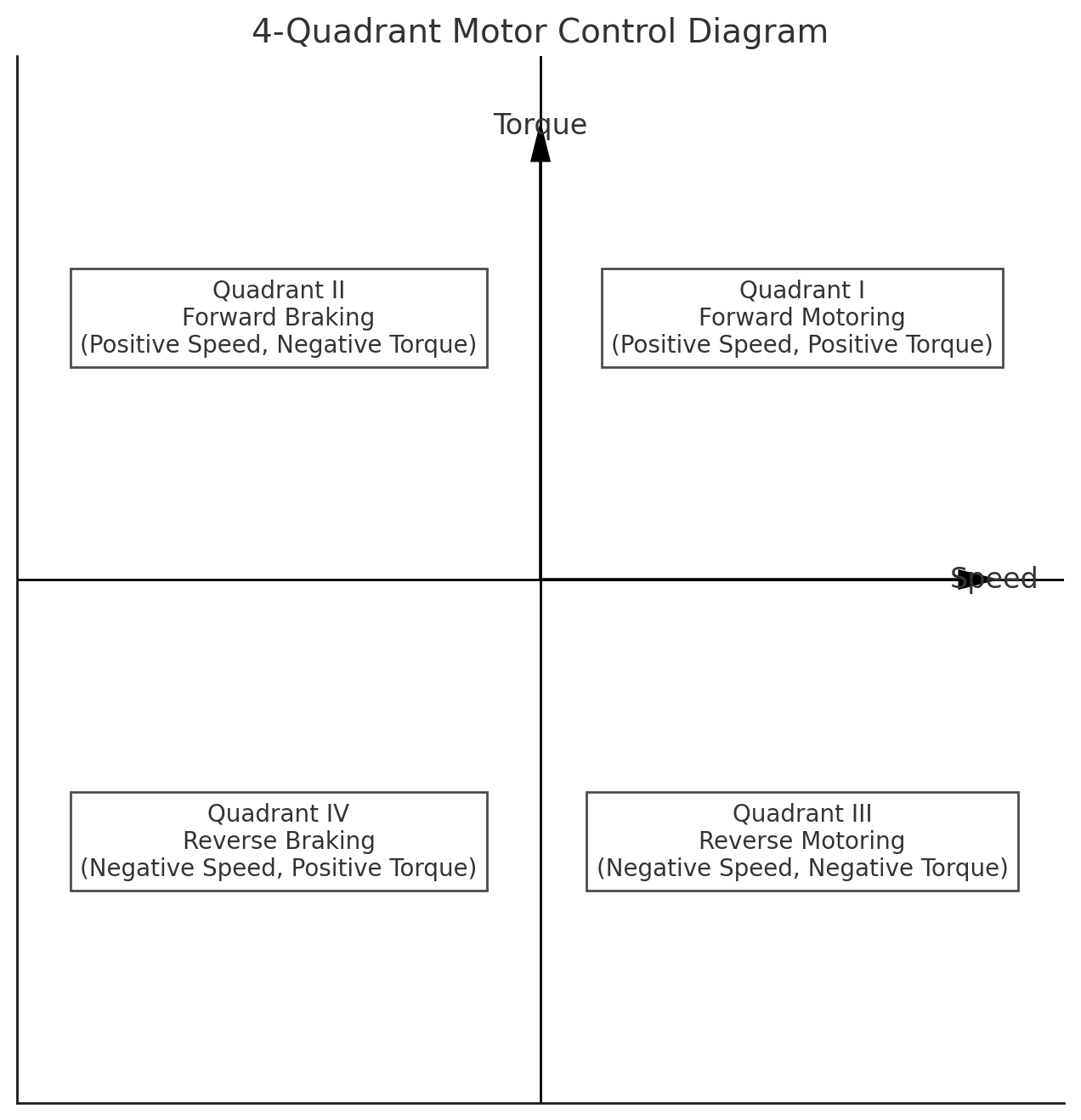

In motor control, "quadrants" refer to the four possible modes of operation based on motor speed and torque:

- Quadrant I: Forward motoring (positive speed, positive torque).

- Quadrant II: Forward braking (positive speed, negative torque).

- Quadrant III: Reverse motoring (negative speed, negative torque).

- Quadrant IV: Reverse braking (negative speed, positive torque).

A motor controller capable of operating in all four quadrants allows the motor to switch seamlessly between driving and braking in both directions. This capability is essential in applications requiring bidirectional operation, precise control, and energy-efficient braking.

The Sensorless Advantage

Traditional BLDC motor control relies on position sensors such as Hall-effect sensors or encoders to determine rotor position. Sensorless control eliminates the need for these physical sensors by using algorithms to estimate rotor position from electrical feedback, such as back electromotive force (back-EMF). This brings several advantages:

- Reduced Cost and Complexity: Eliminating physical sensors reduces hardware costs, simplifies motor design, and enhances reliability by removing components prone to mechanical wear or failure.

- Improved Reliability in Harsh Environments: In applications exposed to extreme temperatures, vibrations, or contaminants, removing sensors enhances system durability and performance.

- Compact Design: Sensorless control reduces the size and weight of the motor assembly, which is critical in applications like drones, robotics, and portable devices.

Benefits of 4-Quadrant Sensorless Control

Combining sensorless control with four-quadrant operation creates a powerful motor control strategy with the following benefits:

1. Enhanced Energy Efficiency

Four-quadrant control enables regenerative braking, where the motor acts as a generator to convert kinetic energy back into electrical energy during braking. This energy can be stored in batteries or fed back into the power grid, significantly improving energy efficiency in systems like electric vehicles (EVs) and industrial drives.

Sensorless control further enhances efficiency by reducing the power consumption of auxiliary systems (like sensors) and optimizing the motor's performance through precise control algorithms.

2. Versatility in Applications

The ability to operate in all four quadrants makes this control strategy ideal for applications requiring frequent transitions between driving and braking, forward and reverse. Examples include:

- Electric Vehicles: Enables smooth acceleration, deceleration, and regenerative braking.

- Conveyor Systems: Supports precise bidirectional movement and controlled stopping.

- Robotics: Facilitates complex maneuvers, such as rapid direction changes and controlled braking.

In such scenarios, sensorless control adds value by reducing system size, complexity, and maintenance requirements, making the solution scalable across diverse use cases.

3. Improved Control Precision

Sensorless control relies on advanced algorithms to estimate rotor position and speed. These algorithms are continuously refined to provide precise, real-time data. When integrated with four-quadrant operation, this level of control precision allows:

- Smooth Transitions Between Modes: Seamless switching between motoring and braking modes, improving performance in dynamic environments.

- Accurate Speed and Torque Control: Critical for applications requiring high levels of precision, such as medical devices and laboratory equipment.

4. Reduced Maintenance and Downtime

Physical sensors in traditional motor systems are vulnerable to mechanical wear, alignment issues, and environmental damage. Sensorless control eliminates these vulnerabilities, resulting in:

- Lower Maintenance Costs: Fewer components to inspect, replace, or recalibrate.

- Increased System Uptime: Enhanced reliability ensures continuous operation, particularly in critical systems like manufacturing lines or aerospace applications.

5. Cost Savings

The combined benefits of sensorless and four-quadrant control result in substantial cost savings over the motor system's lifecycle. Key contributors to cost efficiency include:

- Lower Initial Investment: Sensorless motors are less expensive to manufacture.

- Energy Savings: Regenerative braking and optimized operation reduce energy bills.

- Reduced Repairs and Replacements: Higher reliability and fewer components lead to lower maintenance costs.

6. Environmental Benefits

With global industries emphasizing sustainability, four-quadrant sensorless control aligns perfectly with green initiatives:

- Energy Recovery: Regenerative braking contributes to energy conservation.

- Material Efficiency: The removal of sensors reduces material use during manufacturing.

- Extended Product Life: Enhanced durability minimizes waste and the need for replacements.

These benefits make this technology particularly attractive in eco-conscious industries like renewable energy, electric transportation, and smart buildings.

Explore 4 quadrant brushless DC controllers from Zikodrive

Real-World Examples

Several industries already leverage the advantages of four-quadrant sensorless BLDC motor control:

- Automotive: Electric and hybrid vehicles use this control strategy to deliver smooth driving experiences, extend battery life, and improve overall energy efficiency.

- Aerospace: Drones and unmanned aerial vehicles benefit from compact, lightweight, and reliable motor systems with precise bidirectional control.

- Industrial Automation: Conveyor belts, hoists, and robotics systems achieve high efficiency and precise control, even in challenging operating conditions.

Challenges and Considerations

While the benefits are significant, implementing four-quadrant sensorless control requires addressing challenges such as:

- Algorithm Complexity: Developing and fine-tuning control algorithms demands expertise and computational resources.

- Startup Conditions: Sensorless control can be less effective at very low speeds where back-EMF signals are weak.

- System Design: Ensuring compatibility between motor and controller requires careful planning and testing.

However, advancements in microcontroller technology and control software are rapidly overcoming these challenges, making this approach increasingly accessible.

Conclusion

Four-quadrant sensorless BLDC motor control represents the pinnacle of modern motor technology, combining efficiency, precision, and reliability. Its benefits, including energy savings, versatility, and reduced maintenance, make it an ideal choice for applications ranging from electric vehicles to industrial automation. By addressing the challenges associated with implementation, this technology has the potential to transform motion control systems across industries, setting a new standard for performance and sustainability.

Find out more about our 4 quadrant sensorless BLDC motor controllers and how they can help your project.