Introduction

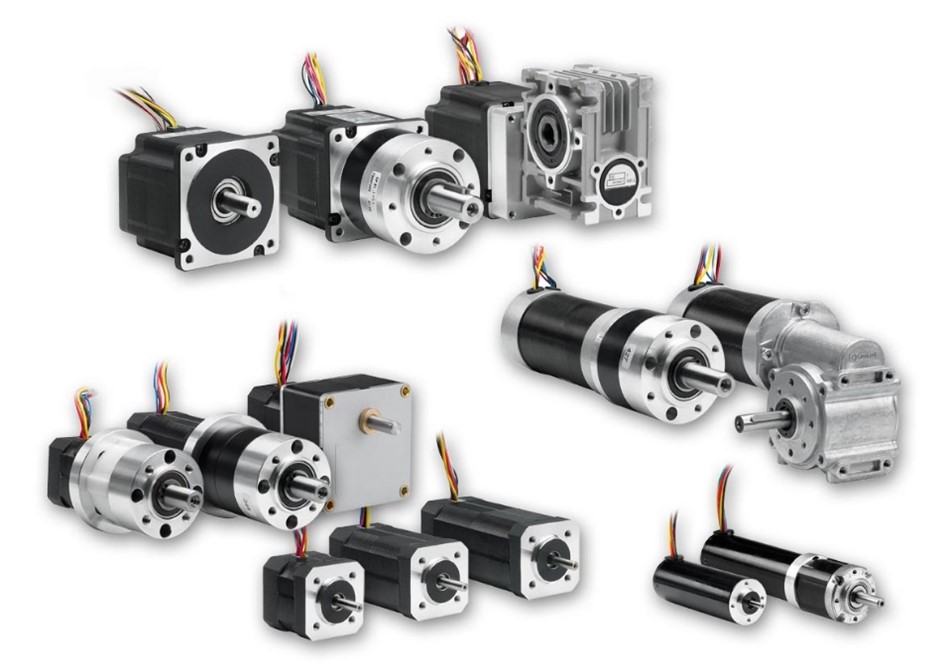

Brushless DC (BLDC) motors offer numerous advantages over their brushed counterparts, including higher efficiency, reliability, and better controllability. However, choosing an appropriate BLDC controller for your applications can be a challenging process. There are a lot of factors to consider and navigating them all can be overwhelming at times. Once the controller is chosen, that is just half the battle, setting it up and calibrating it for your specific application is an entirely different process.

Considering the difficulties faced by a lot of motor control enthusiasts, we at Zikodrive decided to do something about it. So, here is a blog which takes you through the entire process and divides the problem into steps which a user can follow to successfully set up a controller and make sure that it works with your application.

Understanding Sensorless BLDC control:

Sensorless BLDC control relies on the back electromotive force or BEMF produced by the motor windings to determine the rotor position. This eliminates the need for Hall sensors or encoders, simplifying the motor design and reducing costs. However, achieving reliable sensorless control requires precise algorithms and with certain drive methodologies it can require careful calibration in order to deliver the desired performance.

Choosing an appropriate controller:

STEP 1: Motor Identification

Before you can start thinking about the controller to use, you need to identify the electrical parameters of the motor you want to use. This includes the motor’s resistance, inductance, BEMF constant, the number of poles, the current and power rating. You will generally find all the information needed on the datasheet of the motor you plan to use which is provided by the motor manufacturer. To verify the BEMF constant you can use methods such as open loop and closed loop BEMF estimation.

STEP 2: Hardware selection

Start by selecting a sensorless BLDC controller that suits your application requirements. In order to do that you will need to consider factors such as voltage and current ratings, communication interfaces (e.g., PWM, UART, CanBus, etc), and additional features like overcurrent and overvoltage protection, reverse polarity protection, temperature protection, fault detection, etc. Once you have these clear, you can start looking at various options. Also consider if the controller you are looking at will be able to drive the chosen motor successfully in your specific application (for example rapid load changes can cause problems for certain types of brushless DC controller).

STEP 3: Commutation Strategy

Commutation is a process that manipulates currents in inductors to build magnetic fields in motors to ‘pull’ the motor-rotor around. Properly ‘commutating’ a motor means properly aligning this magnetic field to produce maximal torque. The commutation strategy plays a key role in ensuring whether your controller can effectively drive your motor. There are various commutation methods but the most common methods include sinusoidal and trapezoidal commutation.. Each method has its advantages and disadvantages, so be careful when choosing the correct commutation strategy for your application.

Interested in finding out more about how sensorless motors work? Watch the video above.

Once you have successfully followed the above steps, you have the correct motor for your application and you have the correct controller to drive that motor. The next few steps will take you through the process of calibrating and tuning your controller to make sure that your system works in the most efficient manner.

Setting up and Tuning your controller

STEP 1: Setup and Tuning

Calibrating your controller is extremely important to ensure accurate control of the motor. This involves configuring parameters such as motor phase currents, speed and torque limits, and control loop gains. A self-calibrating algorithm for BEMF can also be useful in this regard. Fine-tuning these parameters optimizes motor performance and efficiency. A general rule of thumb is to start with the values provided in the datasheet of the motor. From there you can fine tune the various parameters and thus have excellent control.

The Zikodrive 1 and Zikodrive 2 above both use auto-optimisation, making the setup of a controller much simpler.

STEP 2: Startup Sequence

Implementing a reliable startup sequence for the sensorless BLDC controller is the next crucial step. This typically involves an initial open-loop startup phase, which essentially means that your controller is not getting any feedback from the motor and the motor spins up using predefined voltage or current ramps. This followed by closed-loop control (which means that the controller is getting feedback from the motor) once the motor reaches a certain speed.

Step 3: Sensorless Operation

Verify the sensorless operation of the BLDC motor under different load conditions and speeds. Monitor motor performance and make adjustments as necessary to improve stability and responsiveness.

Step 4: Testing and Validation

Thoroughly test the sensorless BLDC controller in real-world conditions to validate its performance and reliability. Conduct tests for speed control, torque response, and fault tolerance to ensure robust operation.

Conclusion

Setting up a sensorless BLDC controller requires a systematic approach, from hardware selection and motor identification to calibration and testing. By following these steps and leveraging advanced control algorithms, you can harness the full potential of sensorless BLDC motor control in your applications, achieving high efficiency, precise control, and unmatched reliability.

This whole process can be made easier if you use auto-optimising controllers such as the Zikodrive 1 or the Zikodrive 2 controllers as these will take much of the optimisation and operation out of this.